We holds ISO9001 and ISO13485、ISO9100、ISO14001 certifications, signifying our commitment to adhering to rigorous quality standards.

We prioritize continuous improvement through our established quality system. Throughout project development and mass production control, we extensively utilize DFM, FMEA, MSA, Capability Study, Process Validation, and measurement alignment techniques.

"Ensuring Excellence through IQC, IPQC, and OQC."

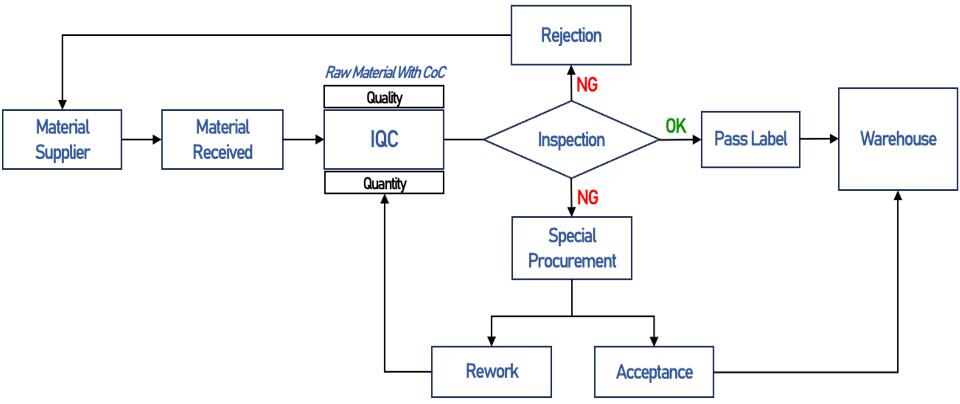

IQC

By rigorously examining and validating raw materials and components prior to production, we proactively detect and mitigate potential issues, minimizing the impact of inferior inputs on the final product.

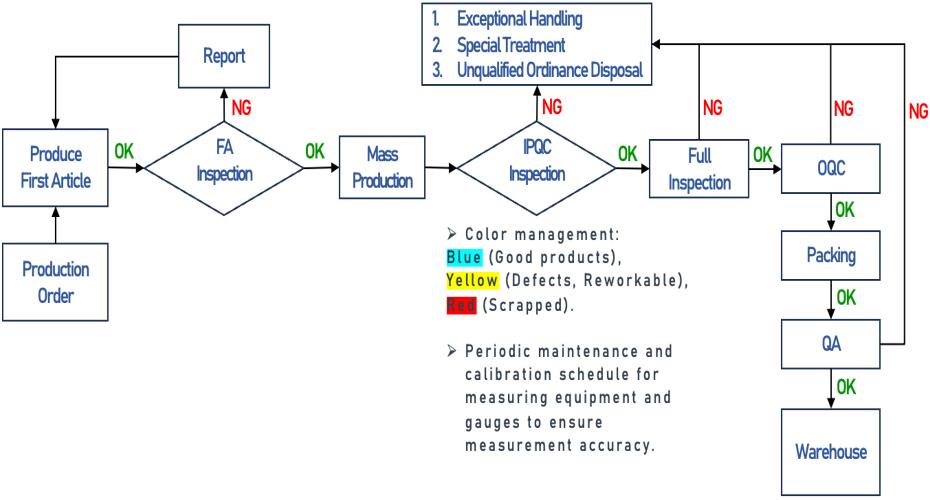

IPQC

Our vigilant team consistently monitors and assesses production quality through bi-hourly inspections and tests, promptly addressing any deviations or non-conformities to ensure our products meet desired specifications and requirements at every step.

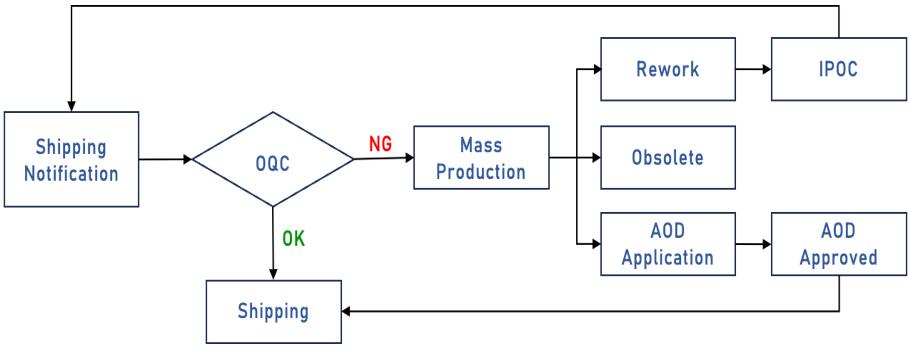

OQC

We conduct rigorous inspections, perform functional tests, and evaluate overall product performance to guarantee that only top-quality goods reach our valued customers.